Handmade

paper (tesuki washi) was invented in AD 105 by a Chinese official

named Cai Lun, and introduced to Japan in AD 610 by Doncho, a monk

from Korea. Sekishu washi, the special handmade paper of western Shimane

Prefecture, also has a long history over a thousand years long. The

name Sekishu washi comes from the fact that it was first produced

in Sekishu (present-day Iwami). It is also known as Sekishu-hanshi

(half-sheets from Sekishu) because of the cut of the paper.

Historically, the Sekishu washi appeared for the first time in records

from AD 905. In those records, Sekishu was one of 42 regions where

20 year-old men were obliged to deliver materials for the local speciality

washi as tax in kind. The name is probably much older, however, as

the 1798 book Kamisuki Chohoki (A Handy Guide to Papermaking), written

by Kunisaki Jihei, says that Kakinomoto Hitomaro, a leading official

in the area, taught people how to make washi sometime around AD 704-715.

If that is true, then not only is Sekishu an old name but, more importantly,

it shows that tesuki washi has been produced in the Iwami region for

about 1300 years.

Making Sekishu-hanshi was a side business for almost all families

in days of old. With the introduction of machinery, however, the 6377

families engaged in the business in 1894 decreased to 664 by 1940

and to 60 by 1965. There are now only 10 families making washi in

this region 6 in Misumi, 1 in Sakurae, and 3 in other localities.

Consequent to the drop in the number of washi makers, the manner of

business changed from a side job to a principal occupation. Those

now engaged in the work have found successors and carry out the traditional

techniques required for making this type of Japanese paper.

Sekishu-hanshi is made from processed bark fibers of three shrubsムkozo

(paper mulberry), mitsumata (Edgeworthia papyrifera), and gampi (Wikstroemia

sikokiana). A vegetable starch known as neri derived from the tororo-aoi

(Hibiscus manihot Medikus) is also added for kneading. After the initial

processing, the pulp solution is molded with bamboo or reed mats (su)

using a method called nagashi-suki. Sekishu-hanshi, which is the most

common washi, is produced from high quality kozo cultivated in this

region. The characteristics of this plant have helped make Sekishu-hanshi

famous as a fine, strong, and glossy paper, as indicated by the following

account. Because of its high quality, Sekishu-hanshi was once used

for account books by merchants in Osaka. In case of fire, the merchants

did not hesitate to throw the account books into a well to protect

the records from fire the merchants were not worried about the paper

being damaged by water.

In light of the unique traditional techniques and methods employed

to make Sekishu-hanshi by Sekishu-hanshi Craftsmens Association (Yasuichi

Kubota, President; 8 members), the paper was designated as an Important

Intangible Cultural Property in 1969.

In addition, the Sekishu techniques and methods used for Sekishu-hanshi

have been completely preserved by crafts people in Misumi Town. To

ensure even further improvement of the art, Sekishu Washi Cooperative

(hiroshi Nagami, Representative Chair; 7members) was established,

and in 1989 Sekishu washi was designated a traditional craft by the

Minister of Economy Trade and Industry.

Sekisyu Washi

Washi that has been chosen in the final selection process is cut to

make various paper products.

The technique of making Sekishu washi with kozo,mitsumata, and gampi

fibers is designated an Important Intangible Cultural Asset. These papers

are used to make such products as Japanese painting and calligraphy

paper, paper for dyed products, stationary, post cards, name cards,

notebooks, and traditional Japanese letter paper.

|

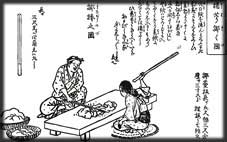

Kamisuki

Chohoki

Harvesting raw

materials

Kamisuki

Chohoki

Steaming branches

|

|

Sekishu kozo paper

The fibers of kozo (Broussonetia Kazinoki Sieb) are about 10 mm long.

By way of comparison, wood pulp fibers are only 1 mm long. Kozo fibers

are tough and mesh easily so that kozo paper retain its strength even

when crumpled or folded.

70% of Sekishu washi is made of kozo fibers.

Sekishu

mitsumata paper

The fibers of mitsumata (Edgeworthia chrysantha Lindle) are about 4

mm long.

They are slightly less strong than gampi and kozo, but they make a finer

and more flexible paper with a special glossy look.

Because of their smooth surface and gentle glossy appearance, mitusmata

is often the paper of choice for Japanese painting and calligraphy.

Sekishu

gampi paper

The fibers of gampi (Diplomorpha sikokiana Honda) average about 3 mm

in length.

The fibers are translucent, glossy and somewhat sticky, making gampi

paper glossy and smooth.

Even if they are put in a humid environment, they will not be damaged,

and they have an inherent resistance against insects.

|

Kamisuki

Chohoki

Making

the sheets

Kamisuki

Chohoki

Drying

|